脱挥(单体)过程

应用范例

弹性体

- 三元乙丙橡胶(EPDM)

- 顺丁橡胶(BR)

- 丁基橡胶(IIR)

- 聚异戊二烯橡胶(IR)

- 溶聚丁苯橡胶(S-SBR)

- 聚烯烃弹性体(POE)

- 丁腈橡胶(NBR)

热塑性弹性体

- 苯乙烯嵌段共聚物(SBS,SIS)

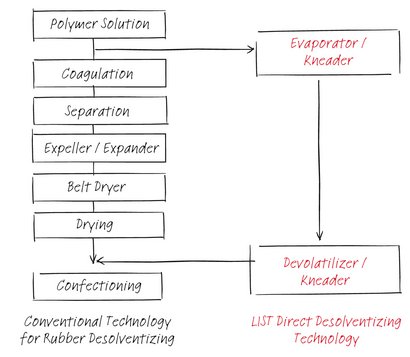

利斯特直接脱挥工艺是各种聚合物和弹性体脱挥发分的最先进,最经济方法的方法。

通过增加产品在工艺腔室中的停留时间,溶剂和残留单体可以更有效的被去除。同时产品破坏性剪切力显着降低。因此,可以实现更好的产品质量,同时最大限度地减少残留挥发物。

利斯特捏合反应器非常适合于在高粘性聚合物溶液中除去残留的挥发物。该技术通常用受到较差传质动力的溶剂去除。为了补偿这种蒸发性能的不足,需要在最低机械热输入下进行高表面更新。

利斯特捏合反应器的大量自由空间有助于在深度真空下运行设备。作为可选项,我们的设备也可以注入其他蒸汽,这将降低溶剂的分压或通过该助剂的蒸发冷却调节所述产品的温度。

我们的优势

- 有效的自清洁可以最大限度地减少死区,产品积累和产品分解

- 优秀的揉捏和混合可以有是物料达到更好的均相性

- 表面更新效率高

- 更大的气相自由空间

- 低剪切力

- 狭窄的停留时间分布与广泛而灵活的停留时间范围设置相结合

- 较大的传热面积,利于准确及均一化的温度控制

- 高效的传热

- 换热表面大

- 连续的生产工艺

- 适用于各种高低门尼数的产品

- 从实验到工业装置的工程放大可靠且低风险

相关资料下载

| 标题 | 描述 | 语言 | 发表时间 | 下载 |

|---|---|---|---|---|

| Direct devolatilisation in a closed system | For decades, conventional polymerisation has been the norm in the production of elastomers. The time and cost involved in removing and treating solvents in the final stages of production were acceptable. Yet as pressure builds on manufacturers to reduce operating costs, there is greater urgency to develop processes that can help streamline costs and production techniques. One such effort has yielded extremely promising results. | English | 2015 | |

| Efficient and eco-friendly polymerization of elastomers | For decades, conventional polymerization in the production of elastomers has been the norm. The time and cost involved in removing and treating solvents in the final stages of production, for example, were acceptable. But as pressure builds on manufacturers to reduce operating costs, there is greater urgency to develop processes that can help streamline cost and production. One such effort by List AG has yielded promising results. | English | 2014 | |

| Efficient & Easy Elastomer Processing | Conventional polymerisation in the production of elastomers has been the norm for decades. The time and cost involved in removing and treating solvents in th e final stages of production , for example, were acceptable, but as pressure builds on manufacturers to reduce operating costs, there is greater urgency to develop processes that can help streamline cost and production. One such effort has yielded extremely promising results. | English | 2013 | |

| Continuous masterbatch process for the cellulose fiber industry | The achievable final volatile content within kneader devolatilization processes is highly dependent on the final melt temperature. For thermosensitive polymers the state of the art process performs poorly. The amount of dissipated energy leads to a heat up of the polymer, limiting the maximal kneader shaft speed and therefore volatile removal rate. This new process uses a suitable additional volatile compound to cool off the dissipated energy by evaporation using the off gas to strip and boost the mass transfer coefficient. A complex multi-parameter study is presented, to predict performance of industrial equipment from pilot scale data. | English | 2011 | |

| New devolatilization process for thermosensitive and highly viscous polymers in high volume Kneader Reactors | The achievable final volatile content within kneader devolatilization processes is highly dependent on the final melt temperature. For thermosensitive polymers the state of the art process performs poorly. The amount of dissipated energy leads to a heat up of the polymer, limiting the maximal kneader shaft speed and therefore volatile removal rate. This new process uses a suitable additional volatile compound to cool off the dissipated energy by evaporation using the off gas to strip and boost the mass transfer coefficient. A complex multi-parameter study is presented, to predict performance of industrial equipment from pilot scale data. | English | 2011 | |

| Kneten statt strippen | Der Einsatz von großen Lösemittelmengen in Polymerisationsprozessen mit den damit verbundenen Nachteilen muss nicht sein. Ein optimiertes Verfahren ermöglicht die direkte Entgasung von Lösemitteln, ohne dabei Strippmittel einsetzen zu müssen. Aufwendige Trennschritte werden so vermieden und höhere Produktqualitäten können erreicht werden. | Deutsch | 2010 | |

| Schritt in eine neue Welt | Der Einsatz von großen Lösungsmittelmengen in Polymerisationsprozessen mit den damit verbundenen Nachteilen muss nicht sein. Ein neues Verfahren beschreitet neue Wege: Kneten statt strippen lautet die Devise. | Deutsch | 2010 | |

| Predition of mass transport of solvent / polymer systems in high volume Kneader Reactors at finite solvent concentrations | Kneader reactors are used for combined unitary processing in the polymer industry for devolatilization, compounding or polymerization. In the past, mass transport prediction for devolatilization operations in kneader reactors did not match experimental results, when diffusion was assumed as sole driving force. It was detected that there is an additional concentration and temperature dependent driving force that triggers enhanced transport at finite solvent concentrations by orders of magnitude. The author suggests that the underlying root cause is likely micro bubble formation within the polymer melt. An attempt to model this additional mass transport mechanism is presented. | English | 2008 | |

| Kneader technology for the direct devolatilitation of temperature sensitive elastomers | Synthetic elastomers have been produced for over 50 years. Advances in catalyst systems and polymer formulations have been somewhat diminished by the continued use of the same processing technology. In particular, the use of coagulation, steam stripping, mechanical dewatering, and convective drying for the devolatilization of temperature sensitive elastomeric solutions can be replaced with direct devolatilization using kneader technology. A two-step, direct devolatilization process has demonstrated energy savings and advantages in environmental emissions and process/product flexibility when compared to the conventional steam stripping process. | English | 2008 | |

| Ohne Wasserdampf zum Kautschuk | Die Synthese von Kautschuk ist ein wichtiger Prozess: Hersteller von Gummiprodukten – ganz gleich ob Autoreifen oder Kondome – benötigen hochwertigen Kautschuk als Ausgangswerkstoff. Doch die Kautschukerzeugung ist teuer und verschlingt große Mengen an Energie. Forschern des Fraunhofer-Instituts für Angewandte Polymerforschung IAP in Potsdam ist es gemeinsam mit ihren Entwicklungspartnern LIST AG und Dow Olefinverbund GmbH gelungen, den Energiebedarf der Kautschuksynthese um 76 Prozent zu senken. | Deutsch | 2007 | |

| Somethin special in separation technology | The synthesis of most elastomers is carried out either by Solution or emulsion polymerization. After the polymcrization step, the polymer is separated from the solvent or emulsifying agents. This separation requires several process steps including coagulation, Stripping, various mechanical separation stages, and finally diying. Beyond that, the existing technologies are energy consuming, waste solvent must be incinerated, and the installation of main and ancillaiy equipment occupies large spaces. | English | 2007 | |

| Eindampfung und Entgasung von Polymerschmelzen | Die bestehenden Technologien für die Aufbereitung von Polymeren nach der Polymerisation können in ein-, zwei- und mehrstufige Verfahren unterteilt werden. Dem entsprechend kommen Stripptechnologien mit nachgeschalteter mechanischer und thermischer Entfernung der Hilfsmittel, Extruder in verschiedenen Bauarten und großvolumige Kneter zum Einsatz. Die Knetertechnologie ist vor allem für temperatur- und scherempfindliche Polymermassen geeignet, bei denen die Entgasung diffusionsbestimmt ist. | Deutsch | 2006 | |

| Kontinuierliche Eindampfung und Entgasung von Polymerschmelzen | Polymerprozesse – Aufbereitung und Finishing von Polymeren – Knetertechnologie in der Polymeraufbereitung – Wirtschaftlichkeit | Deutsch | 2006 | |

| Torque and speed fluctuation on polymer processing large volume kneader | Large volume kneaders are designed to handle highly viscous polymer processing. The unitary operations can be compounding, polymerizations, devolatilization or drying. Depending on the polymer viscosity in the kneader, the interaction of kneading elements induce a torque and force evolution on the shaft over one revolution. | English | 2006 | |

| Computer Berechnung des Scale up für Entgasungsvorgänge in Knetreaktoren | Eine konzentrierte Elastomerlösung (weniger als 20 % Lösungsmittel) wird einem großvolumigen Knetreaktor zugeführt, um das Lösungsmittel bis auf ppmGehalte zu entfernen. Um diesen Entgasungsschritt zu beschreiben, wurde ein Simulationsprogramm entwickelt. Das Programm errechnet den Restlösungsmittelgehalt, den Füllgrad und das Drehmoment des Reaktors. Es kann sowohl der Feineinstellung sowie auch dem Scale-up des Prozesses dienen. | Deutsch | 2005 | |

| Leuchtturm in karger Forschungslandschaft | Das Fraunhofer-Pilotanlagenzentrum für Polymersynthese und -verarbeitung | Deutsch | 2005 | |

| Computer scale up model for Desolventizing highly viscous polymers | A concentrated rubber solution (less than 20 % solvent) is fed to a high volume kneader in order to remove the solvent down to ppm level. A simulation program has been developed to describe this devolatilization step. The program predicts final solvent content, the filling level and the mechanical torque build-up. The program can be used to refine process control and the scale-up of this type of process. | English | 2005 | |

| Comparison devolatilization technologies for viscous polymers | Devolatilization of solvents from viscous polymer cement is realized through stripping of solvent with steam in stirred vessels or directly by evaporating the solvent from the polymer. The later so-called direct desolventizing is realized in extruders or high volume kneaders. All 3 methods involve additional energy to drive out solvent either by partial pressure through additional steam (steam stripping), building and releasing pressure in order to explode the polymer bulk (extruder) or dynamic surface renewal (kneader). | English | 2005 | |

| LIST im Demo Zentrum Polymersynthese | Energieeinsparung und Qualitätsverbesserung durch indirekte Eindampfung von Polymerlösungen oder direkte Polymerisation und Polykondensation | Deutsch | 2004 | |

| Finishing reaction of PA6 in the melt phase | The difference in the production of PA6 in comparison to that of other polymers is the downstream water extraction and drying after the granulation. During these process steps, the monomer and the oligomer contents in the final product are reduced in the 0.2 to 0.6 ww/w range. The installed units for extraction and drying of the final granulated product are characterized by their large energy consumption, which considerably influences manufacturing costs. | English | 2002 |