工艺开发与系统集成

工业过程无时不刻不面临着来自系统集成、清洁生产以及持续改进等方面的压力。同时,环保方面的压力也推动着生产企业在降低物耗与能耗、减少或避免有害物质、减少排放以及废弃物的产生等方面不断提升与改进。

作为工艺过程的核心,利斯特捏合型反应器技术能够帮助客户达成上述目标!我们在化学工程、工艺过程以及机械工程方面的综合能力,与我们在系统工程方面累积的声名卓著的知识相结合,使我们自身成为客户在开发具有创新性及经济性工艺过程时独一无二的百宝箱。

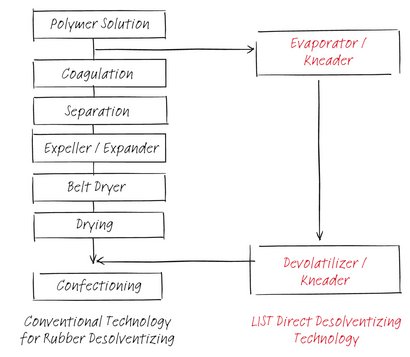

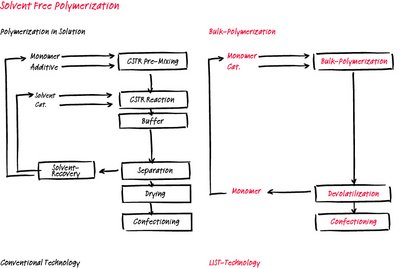

利斯特产品在高浓缩相的工艺条件下表现出卓越的性能,尤其在减少或避免使用溶剂方面,能够有效的帮助客户应对在降低成本方面持续上升的需求。利斯特的终极目标是帮助客户在降低投资及生产成本、提升产品质量以及操作可靠性等多方面取得最优的回报与收益!

我们的优势

- 高效的自清洁作用能够最大限度的减少死区的产生、物料的累积以及降解等现象;

- 优异的捏合及混合作用利于物料体系均匀同质化;

- 较低的过程剪切力;

- 高效的能量传递;

- 较高的表面更新率;

- 较大的汽相自由扩散空间;

- 较大的传热面积,利于准确及均一化的温度控制;

- 工艺过程可设计为连续化操作;

- 适合黏稠或高粘度物系的工艺需求;

- 较宽且可灵活调整的平均停留时间区间;

- (反混设计)可使停留时间灵活满足工艺需求;

- 从实验到工业装置的工程放大可靠且低风险;

- 过程转化率较高;

- 聚合物分散指数(PDI)可达2~2.5之间;

- 反应过程可在近似精确计量条件下进行;

相关资料下载

| 标题 | 描述 | 语言 | 发表时间 | 下载 |

|---|---|---|---|---|

| Reactor for solvent-free polymer processing | Converting the polymer industry to solvent-free polymerisation processes and avoiding unnecessary recirculation decreases energy consumption and reduces waste production. This can be achieved with the horizontal large-volume Kneader Reactor with superior mixing and homogenisation performance. The casing, shafts and mixing elements are indirectly heated by heat transfer fluids and dynamically self-cleaning. | English | 2012 | |

| Ganz ohne Lösungsmittel – Syntheseverfahren in der konzentrierten Phase | Mit lösemittelfreier Prozessführung, dem sogenannten Dry Processing, lassen sich zwei entscheidende Ziele erreichen: umweltfreundliche Prozesse und eine deutliche Senkung der Investitions- und Betriebskosten. Die Schweizer Firma List konzentriert sich dabei nicht auf einzelne Verfahrensschritte, sondern auf den Prozess als Einheit, um eine ganzheitliche verfahrenstechnische und wirtschaftliche Optimierung zu erreichen. | Deutsch | 2009 | |

| Es geht auch ohne Lösungsmittel | Sie suchen ein lösungsmittelfreies, sicheres, umweltfreundliches und energieeffizientes Herstellungsverfahren, das neue Produkttypen mit neuen Qualitätsmerkmalen hervorbringt? Eine neue Technologie macht’s möglich. | Deutsch | 2009 | |

| Saying goodbye to solvents | Are you looking for a solvent-free, safe, eco-friendly and energy-efficient way of producing new types of products with new levels of quality? New technology is available to help you do exactly that. | English | 2009 | |

| Prediction of Kneader Reactor Bulk Co-Polymerization Continuous Processes | Batch trials were performed on a kneader reactor where a bulk co-polymerization was carried out. Polymerization conversion, viscosity build, reaction kinetics, and heat transfer calculations were performed using the experimental data from the batch trials. A continuous process was proposed for this bulk copolymerization and the models and results from the batch trials were used in designing the continuous process. Predictions of the continuous process using the batch trial data are compared to the actual continuous process, with a focus on polymer conversion, heat transfer, and torque prediction. | English | 2007 | |

| Bulk Polymerisation or Copolymerisation in a Novel Continuous Kneader Reactor | A new type of kneader reactor is proposed for the continuous radical (co-) polymerisation without solvent, based on the proven design of mature (kneader-) dryer technology. The reactor has been developed to satisfy all major aspects required for (co-) polymerisation while maintaining the safety and reliability of the previous mechanical design. The new kneader reactor offers a perfect combination of surface renewal and evaporative cooling to control temperature to high conversion (85 to 95%), even for bulk systems that have a strong gel effect (Trommsdorff’s effect) and high exothermicity. | English | 2006 | |

| Bulk polymerisation of MMA in a kneader reactor | The bulk free radical polymerization of methyl methacrylate (MMA) or the bulk free radical copolymerization of MMA based monomer recipes face a gel effect (Trommsdorff’s effect) and exothermicity. The kneader reactor offers a perfect combination of surface renewal and evaporative cooling to control temperature at high conversion (85 to 95%). | English | 2006 | |

| Continous polymerisation | Various types of reactor have been developed to date for improving the stability of the polymerisation process. This review describes a few examples of heterogeneous and homogeneous polymerisation, focusing particularly on viscosity control and heat removal. The production of solid polymer granules directly in a kneader-reactor with evaporative cooling is one efficient and reliable polymerisation technology. | English | 2003 | |

| CKR for continous polymerisations producing solid granular polymers | A review of the existing polymerisation processes is proposed, with particular attention to the control of viscosity and heat removal. Up to the present time, different types of reactor have been developed in order to improve the stability of the polymerisation process. A review of these reactors is presented for the heterogeneous and homogeneous polymerisations. The production of solid polymer granules directly in a kneader reactor under evaporative cooling is seen as an efficient and reliable polymerisation technology. | English | 2001 |