괴상중합

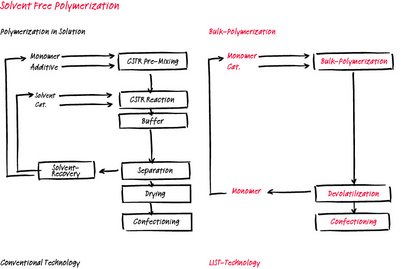

중합체의 제조방법은 통상적으로 다량의 용매를 필요로 합니다. 그러나 리스트 니더반응기(LIST KneaderReactors)를 사용하면 효율적인 대안책을 찾을 수 있습니다. 리스트 니더반응기는 고농축 또는 무용매 상태에서 단량체 및 촉매와 함께 합성이 가능하며 90-99%의 전환율에 쉽게 도달할 수 있습니다. 중합 후단 공정으로, 1000 ppm 이하의 잔류 단량체 함량으로 직탈휘발화 됩니다. 특히 발열 괴상(공)중합 공정에서 리스트의 니더반응기의 큰 열교환 표면은 증발냉각과 함께 중합체의 온도를 정확하게 제어하는 역할을 합니다. 혼합요소(mixing elements)들의 독특한 기하학적 구조는 열전달을 최적화하고 제품 축적 및 데드존을 최소화하고 일정한 표면 갱신을 제공합니다.

특이사항

- 효과적인 셀프 클리닝으로 인한 데드존, 제품 축적 및 분해산물의 최소화

- 최적의 반죽 및 믹싱으로 인한 우수한 균일화

- 저전단 공정

- 효과적인 열전달

- 고효율 표면 갱신

- 광범위한 프리(free)증기부피

- 광범위한 전열면적으로 인한 정밀하고 균일한 온도 컨트롤

- 연속 공정

- 점착성이 있거나 고점도의 제품처리 공정

- 넓고 유연한 평균 체류시간

- 광범위한 체류 시간 분포 (역혼합)

- 시험/파일럿용 장비부터 공업규모까지 신뢰할 수 있는 스케일업

- 높은 전환율

- 다분산지수 2….2.5

- 거의 화학량적인 조건에서의 반응

사례

폴리메틸메타크릴레이트 (PMMA)

리스트 니더반응기에서 메타크릴산 유도체들의 괴상중합은 98 %가량의 전환율을 이룰수 있습니다 . 또한 2.0 ~ 2.5의 다분산 지수(PDI) 값에 도달 할 수 있습니다.

고흡수성폴리머 (SAP)

아크릴산은 중합체 함량이 최대 45%인 리스트 니더반응기를 통해 수성 괴상중합 상태에서 중합됩니다. 리스트 니더반응기의 정확한 온도 조절은 매우 좁은 다 분산 지수 (PDI) 분포를 초래하며 고흡수성폴리머는 자유유동(free flowing) 물질로 배출됩니다.

다운로드

| 제목 | 설명 | 언어 | 년도 | 다운로드 |

|---|---|---|---|---|

| Reactor for solvent-free polymer processing | Converting the polymer industry to solvent-free polymerisation processes and avoiding unnecessary recirculation decreases energy consumption and reduces waste production. This can be achieved with the horizontal large-volume Kneader Reactor with superior mixing and homogenisation performance. The casing, shafts and mixing elements are indirectly heated by heat transfer fluids and dynamically self-cleaning. | English | 2012 | |

| Ganz ohne Lösungsmittel – Syntheseverfahren in der konzentrierten Phase | Mit lösemittelfreier Prozessführung, dem sogenannten Dry Processing, lassen sich zwei entscheidende Ziele erreichen: umweltfreundliche Prozesse und eine deutliche Senkung der Investitions- und Betriebskosten. Die Schweizer Firma List konzentriert sich dabei nicht auf einzelne Verfahrensschritte, sondern auf den Prozess als Einheit, um eine ganzheitliche verfahrenstechnische und wirtschaftliche Optimierung zu erreichen. | Deutsch | 2009 | |

| Es geht auch ohne Lösungsmittel | Sie suchen ein lösungsmittelfreies, sicheres, umweltfreundliches und energieeffizientes Herstellungsverfahren, das neue Produkttypen mit neuen Qualitätsmerkmalen hervorbringt? Eine neue Technologie macht’s möglich. | Deutsch | 2009 | |

| Saying goodbye to solvents | Are you looking for a solvent-free, safe, eco-friendly and energy-efficient way of producing new types of products with new levels of quality? New technology is available to help you do exactly that. | English | 2009 | |

| Prediction of Kneader Reactor Bulk Co-Polymerization Continuous Processes | Batch trials were performed on a kneader reactor where a bulk co-polymerization was carried out. Polymerization conversion, viscosity build, reaction kinetics, and heat transfer calculations were performed using the experimental data from the batch trials. A continuous process was proposed for this bulk copolymerization and the models and results from the batch trials were used in designing the continuous process. Predictions of the continuous process using the batch trial data are compared to the actual continuous process, with a focus on polymer conversion, heat transfer, and torque prediction. | English | 2007 | |

| Bulk Polymerisation or Copolymerisation in a Novel Continuous Kneader Reactor | A new type of kneader reactor is proposed for the continuous radical (co-) polymerisation without solvent, based on the proven design of mature (kneader-) dryer technology. The reactor has been developed to satisfy all major aspects required for (co-) polymerisation while maintaining the safety and reliability of the previous mechanical design. The new kneader reactor offers a perfect combination of surface renewal and evaporative cooling to control temperature to high conversion (85 to 95%), even for bulk systems that have a strong gel effect (Trommsdorff’s effect) and high exothermicity. | English | 2006 | |

| Bulk polymerisation of MMA in a kneader reactor | The bulk free radical polymerization of methyl methacrylate (MMA) or the bulk free radical copolymerization of MMA based monomer recipes face a gel effect (Trommsdorff’s effect) and exothermicity. The kneader reactor offers a perfect combination of surface renewal and evaporative cooling to control temperature at high conversion (85 to 95%). | English | 2006 | |

| Continous polymerisation | Various types of reactor have been developed to date for improving the stability of the polymerisation process. This review describes a few examples of heterogeneous and homogeneous polymerisation, focusing particularly on viscosity control and heat removal. The production of solid polymer granules directly in a kneader-reactor with evaporative cooling is one efficient and reliable polymerisation technology. | English | 2003 | |

| CKR for continous polymerisations producing solid granular polymers | A review of the existing polymerisation processes is proposed, with particular attention to the control of viscosity and heat removal. Up to the present time, different types of reactor have been developed in order to improve the stability of the polymerisation process. A review of these reactors is presented for the heterogeneous and homogeneous polymerisations. The production of solid polymer granules directly in a kneader reactor under evaporative cooling is seen as an efficient and reliable polymerisation technology. | English | 2001 |